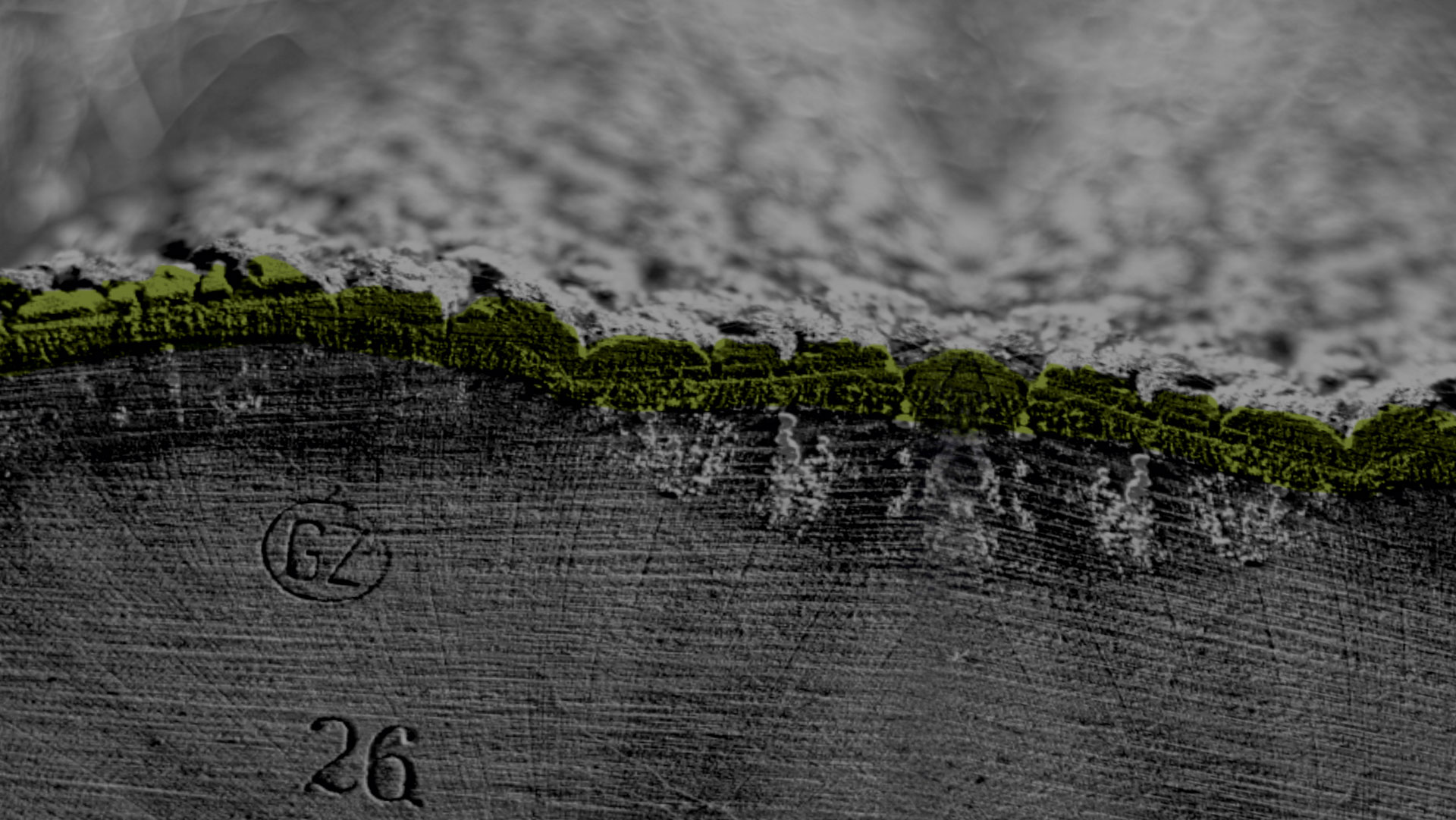

Please fill in the batch # printed on

your tag to trace the origin

and history of your item

With the real care we and the forestry in Europe spend on logs and lumber the value of certificates is still incredibly important. Both FSC & PEFC have done a lot to educate people and prevent deforestation especially in the areas outside of Europe.

If you consider that every tree is unique, often over centuries old before it

can be touched and another 3 trees must be planted for every one cut down it is

obvious that something unique must be done with this.

It is worth to value trackabletree items as specialties now you know their full history.

When buying an item you might want to know the history.

When ready for a change you might want to know the destiny.

Because there is so much valuable we started to offer in certain countries the service to

collect your item and show you how to upcycle the parts into new products.

In fact the circular economy is realized. The former user may see the destiny and the next

user can see the previous one as origin.

Even when you live in countries where we cannot offer an upcycle option we really

love to see how the items fit into your world.

Share pictures and benefit from others.

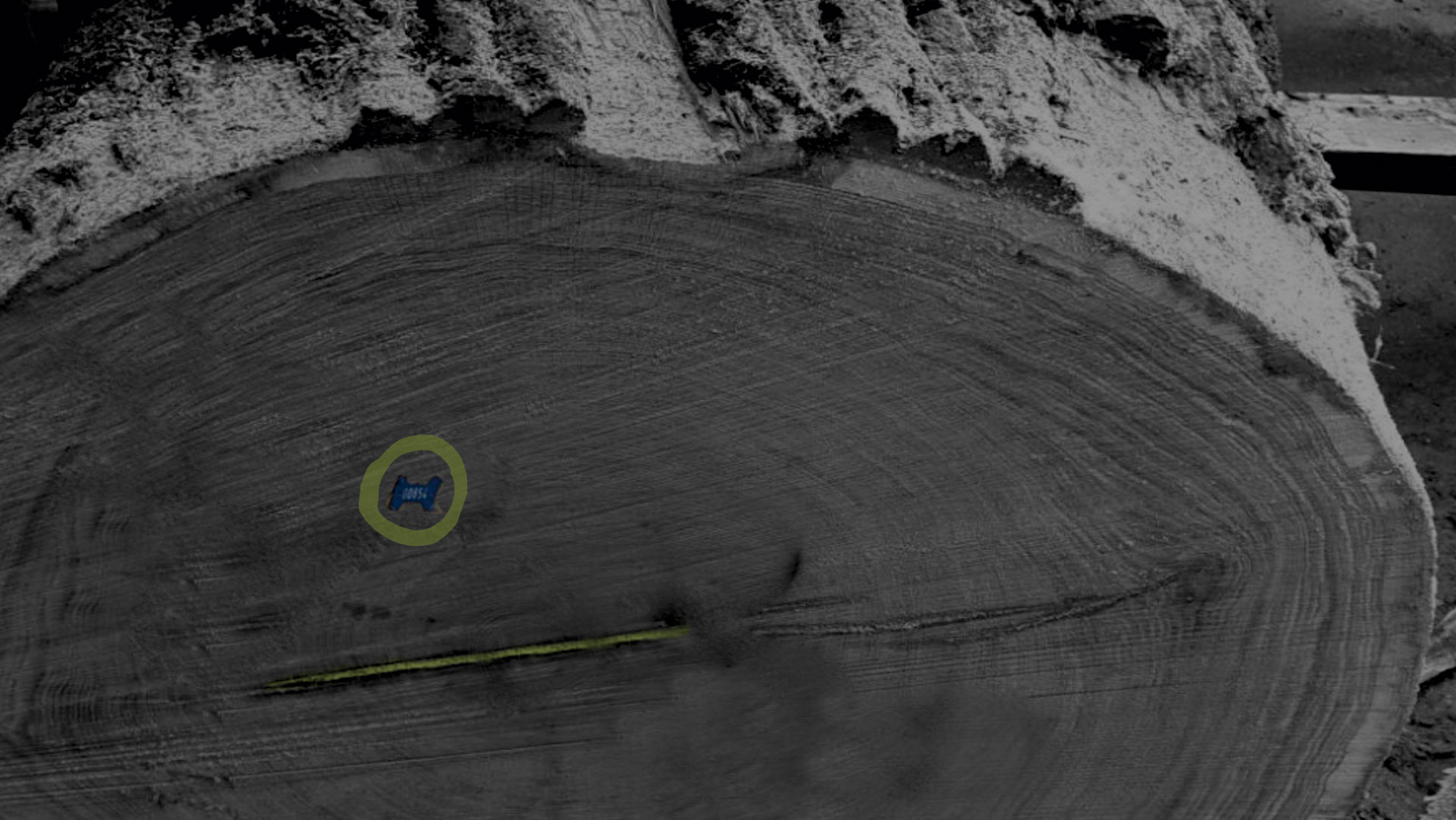

All starts in the forest. Here all trees get an individual number. In every stage of the process we can trace the full history of every single board of this log.

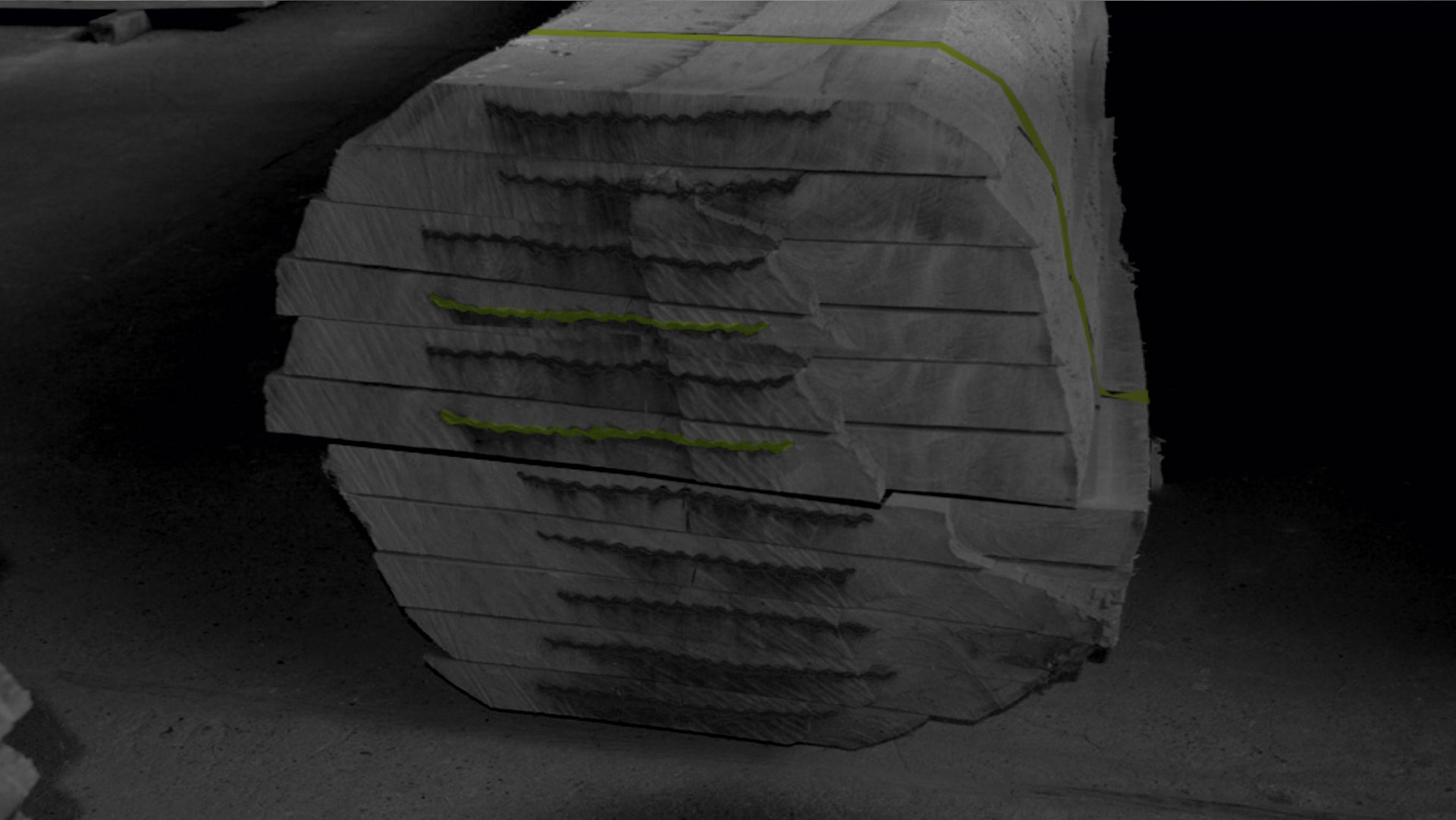

Then the cutting into boards. No mass production but slice after slice is decided for the distinctively large sizing or thinner boards, all based on grain patterns and quality.

Then wood enters its crucial phase. Patience is required to get the moisture content down to about 10%.

The working on solid wood is the final step before delivery. Via the trackabletree system you can see the full production history of who did what and when.

Already for centuries European Oak has been a favorite among skilsmen for its unique, rich, mature close grain. It is warm honey colored when used in house and beautiful grey when outside.

What’s more... it takes centuries before an oak tree can be touched. Unlike pine that is often used when not even 60 years old an oak tree can be easily 200 years old.

Poland is the home of Europe’s largest concentration certified oak forest. This system was implemented due to its political situation and continues to be very carefully managed generation after generation.

TrackableWorld

Quadra Secha

7556 Ramosh - Switzerland

T. + 41-81-8603052

E. reception@trackableworld.com